Precision For Drug Discovery And Development

Thanks to decades of experience in the industrialization of over 100 different test applications, Weidmann Medical Technology is a leader in the development and production of custom-made laboratory products, for example pipette tips and plates with 96 or 384 wells, as well as a variety of custom SBS-footprint micro-titer plates.

We have a broad spectrum of medically-approved plastic materials at our disposal, such as rigid plastics, thermoplastic elastomers and alternate materials such as filters, films, membranes and metallic inserts.

Weidmann Medical Technology supports you in all steps of product development and in parallel creates the User Requirement Specification (URS), the Risk Management Documentation (FMEAs), as well as the Design History Files together with your team.

From a simple hand sketch, through concept studies, product creation and design, rapid tooling and prototyping to raw material selection, cavity design, tool manufacture and process development, we use the most modern technologies such as 3-D modelling via CAD-CAM, Moldflow Analysis, and static and dynamic calculations for part and tooling layouts.

After the URS is approved, the products are developed, produced and industrialized by Weidmann Medical Technology according to cGMP guidelines. Our production technologies and control systems assure complete reproducibility in the entire production process. Through the application of the most modern injection molding and automation technologies, we develop production processes using a combination of elastomers and non-elastomers.

All qualifications- (DQ,IQ,OQ,PQ) and validation processes conform to ISO 13485 and have been certified by the DQS Agency since 2003. Weidmann Medical Technology was audited by the FDA to the CFR820 standard and has been FDA-registered since 2013. All Cmk, Cpk-, Cp, and AQL requirements are fulfilled.

A flexible ERP and Supply Chain Management System enables an optimal logistical structure with both centralized and local production. The supply chain is constantly monitored by active controlling with regard to quality and supply assurance, and optimized by our Supplier Managers.

Diffusion And Filtration Plate (Di-Fi)

This plate can be produced in seven different materials, for example >PP< or >PS<, in order to achieve inert surface properties. Appropriate membranes are welded to the bottom of each well.

Membrane materials >PVDF<, >COC<

Volume: 60µl per well

Nano Aliquot Sample Plate (NASP)

Specially-developed liquid handling plate to achieve volume dispensation with extremely high precision.

Material: >PP<

Volume: 60µl per well

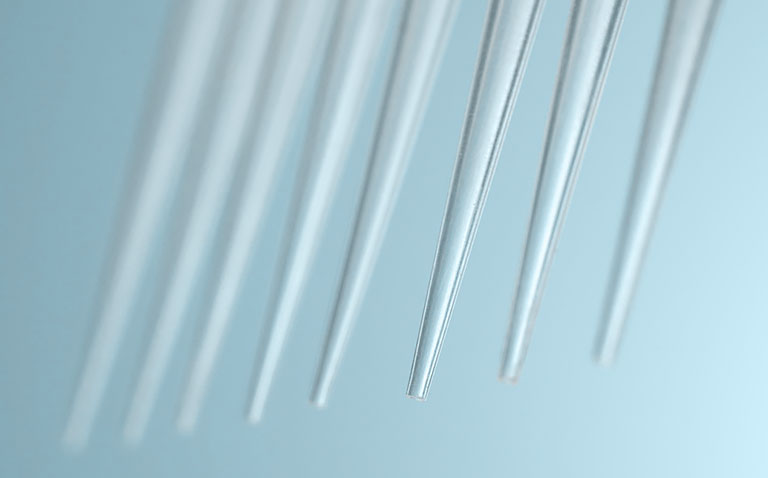

Pipette Tips

Tip orifice size (ID <0,3 mm) and concentricity (R <0,6 mm);

Volumes: 25 ul to 200 µl

A variety of medical grade materials are available.

Materials: >PP<, >PS<, >PC<