Diagnostics

Precision components

for diagnostic systems

Weidmann Medical manufactures high-precision components for diagnostic applications such as PCR cartridges and microfluidic systems. With more than 20 years of experience in replicating fluidic structures in plastics and scaling them for production, we offer cleanroom manufacturing, multi-component molding, and strict quality control for consistent performance and sample integrity across diagnostic platforms.

Advanced laboratory diagnostics

- Fully integrated automation cell with injection molding, 100% in-line camera inspection, assembly, and off-the-shelf packaging

- High-cavity, high-speed cycle times

- Extremely tight tolerances

- >2 billion units per year

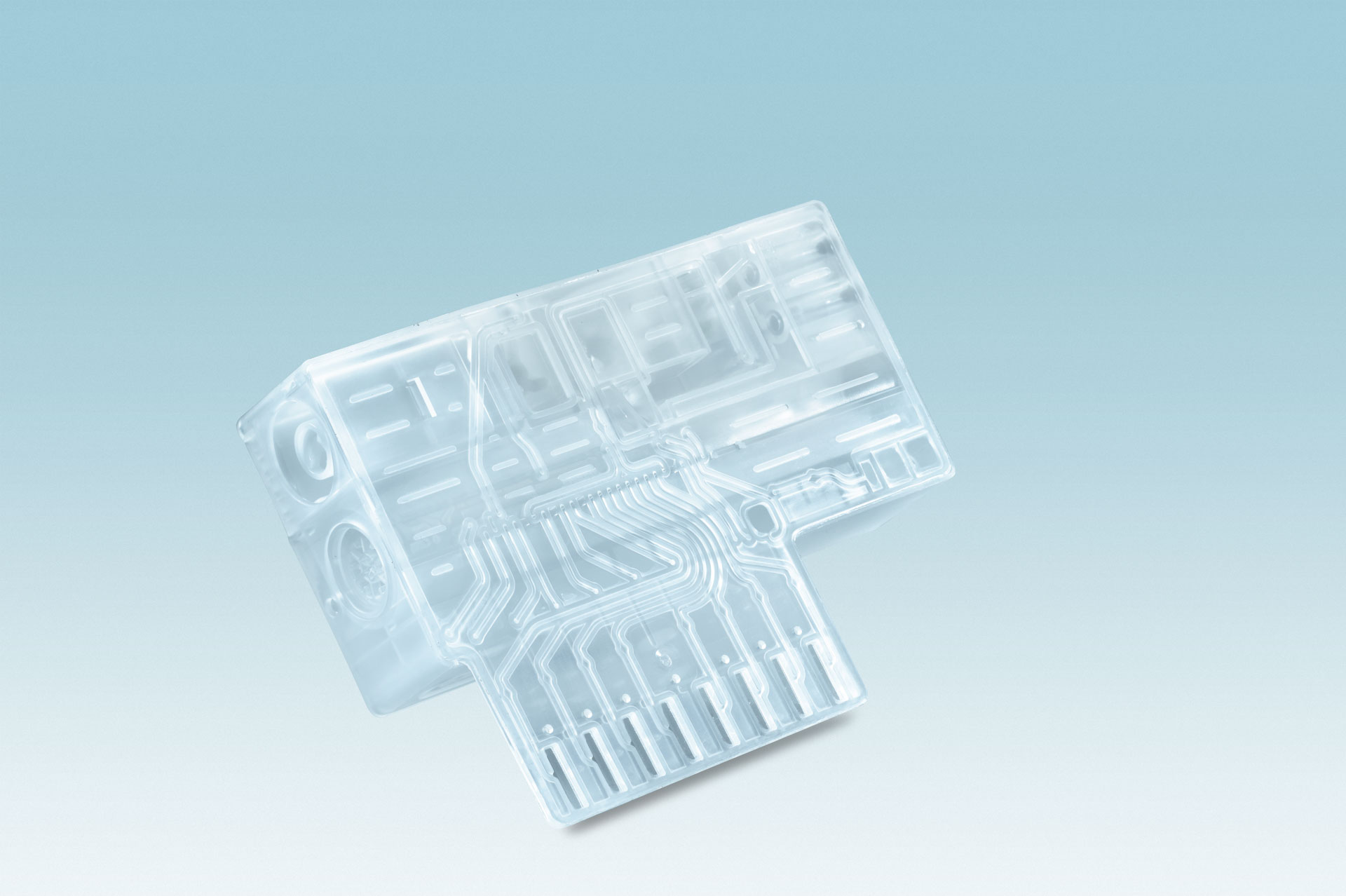

Realtime

PCR cartridge

- Multi-component molding

- Integrated chamber and microfluidic system

Explore tailored solutions – connect with our experts today

Our process

Product design

Industrialization

Process validation

End packaging and logistics

Weidmann Medical supports you in all steps of product development and, in parallel, creates the User Requirement Specification (URS), the Risk Management Documentation (FMEAs), and the Design History Files together with your team.

From a simple hand sketch through concept studies, product creation and design, rapid tooling and prototyping to raw material selection, cavity design, tool manufacture, and process development, we use the most modern technologies such as 3-D modeling via CAD-CAM, Moldflow Analysis, and static and dynamic calculations for part and tooling layouts.

All qualifications (DQ,IQ,OQ,PQ) and validation processes conform to ISO 13485 and have been certified by the DQS Agency since 2003. Weidmann Medical is audited by the FDA to the CFR820 standard and has been FDA-registered since 2013. All Cmk, Cpk-, Cp, and AQL requirements are fulfilled.

An ERP and supply chain management system enables an optimized logistics structure with both centralized and local production. Active controlling ensures continuous monitoring of the supply chain to guarantee quality and delivery reliability, while our supplier managers drive ongoing optimization.