Radio Frequency Identification (RFID)

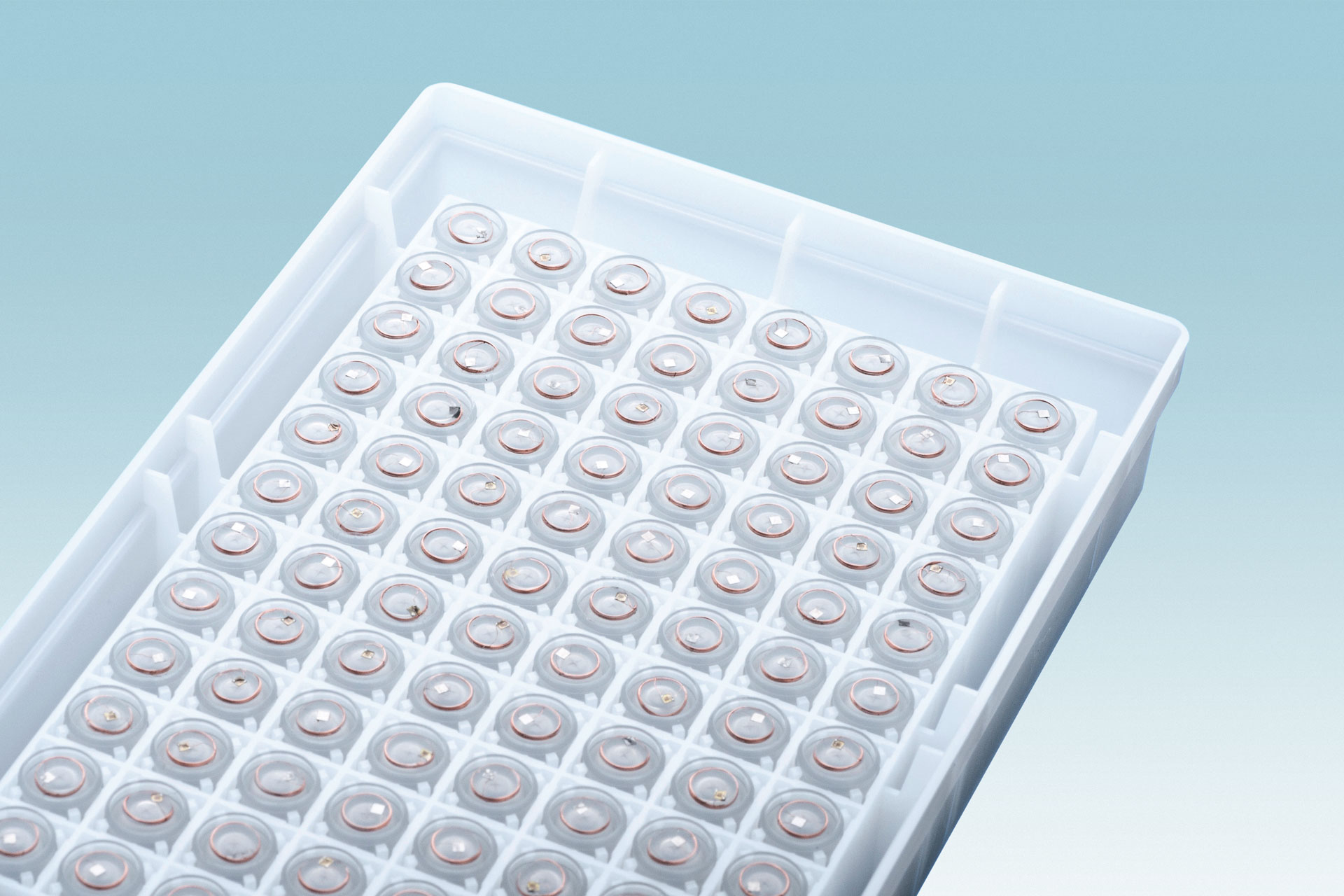

Seamless RFID integration during injection molding

Product identification and environmental condition tracking are becoming increasingly important in laboratory automation and diagnostics. With RFID inlays, you can store, update, and access key product information throughout the entire lifecycle – improving traceability and data management.

At Weidmann Medical, RFID inlays can be placed anywhere on your product or seamlessly embedded in plastics during the injection molding process. Our proprietary technology enables partial or complete encapsulation of RFID tags and chips, protecting sensitive electronics while enabling traceability for disposable materials – helping meet stringent regulatory requirements such as FDA guidelines.

We offer two specialized processes: the overmold process fully encapsulates the inlay for maximum protection against mechanical stress, while the inmold process secures larger inlays using a back-shot technique for lower-stress applications.

Built-in RFID for product intelligence

- Seamless product labeling and traceability

- Integrated data storage throughout the product lifecycle

- Supports temperature and humidity monitoring

- Enhances patient safety and therapy outcomes

- Ideal for auto-injectors, syringes, cartridges, patch pumps